Partner with Experts

Produvia is a software development agency based in Vancouver, Canada. Since 2013, we partnered with startups and enterprises to develop blockchain, deep learning, and quantum technologies.

“Our mission is to transform 100 companies by June 2022.”

Slava Kurilyak, Founder/CEO at Produvia

Produvia Services

Blockchain Development

We help startups develop state-of-the-art blockchain technologies.

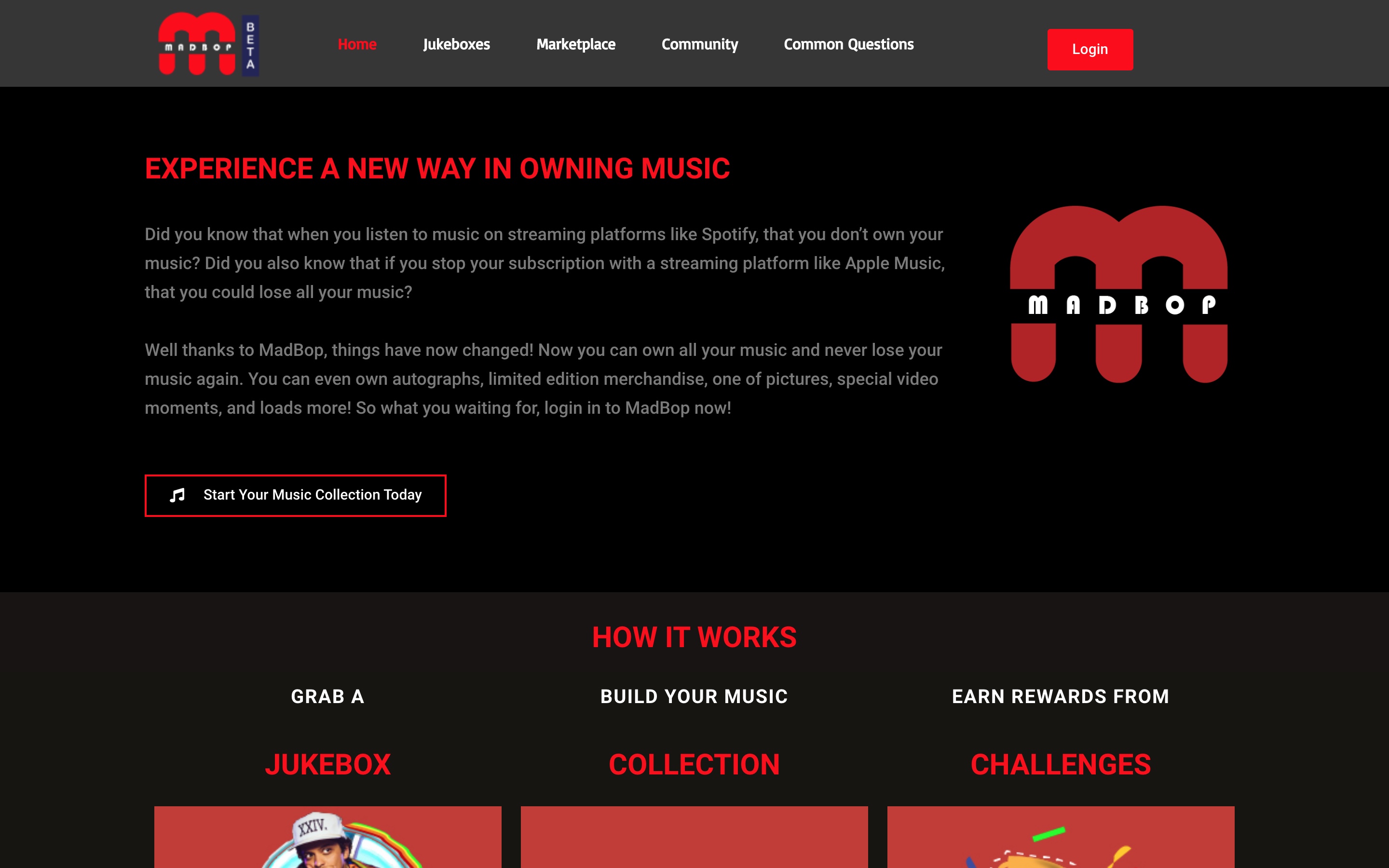

Non-Fungible Token (NFT) Development

Smart Contract Development

Decentralized Application (DApp) Development

Social Token Development

Blockchain Token Development

Blockchain Coin Development

Deep Learning Development

We help enterprises develop state-of-the-art deep learning technologies.

Image Model Development

Language Model Development

Audio Model Development

Sequential Model Development

Graph Model Development

Machine Learning Development

Quantum Development

We help enterprises research start-of-the-art quantum technologies.

Quantum Deep Learning Development

Quantum Approximate Optimization Algorithm Development

Quantum State Tomography Algorithm Development

Quantum Circuit Equivalence Checking

Quantum Circuit Mapping

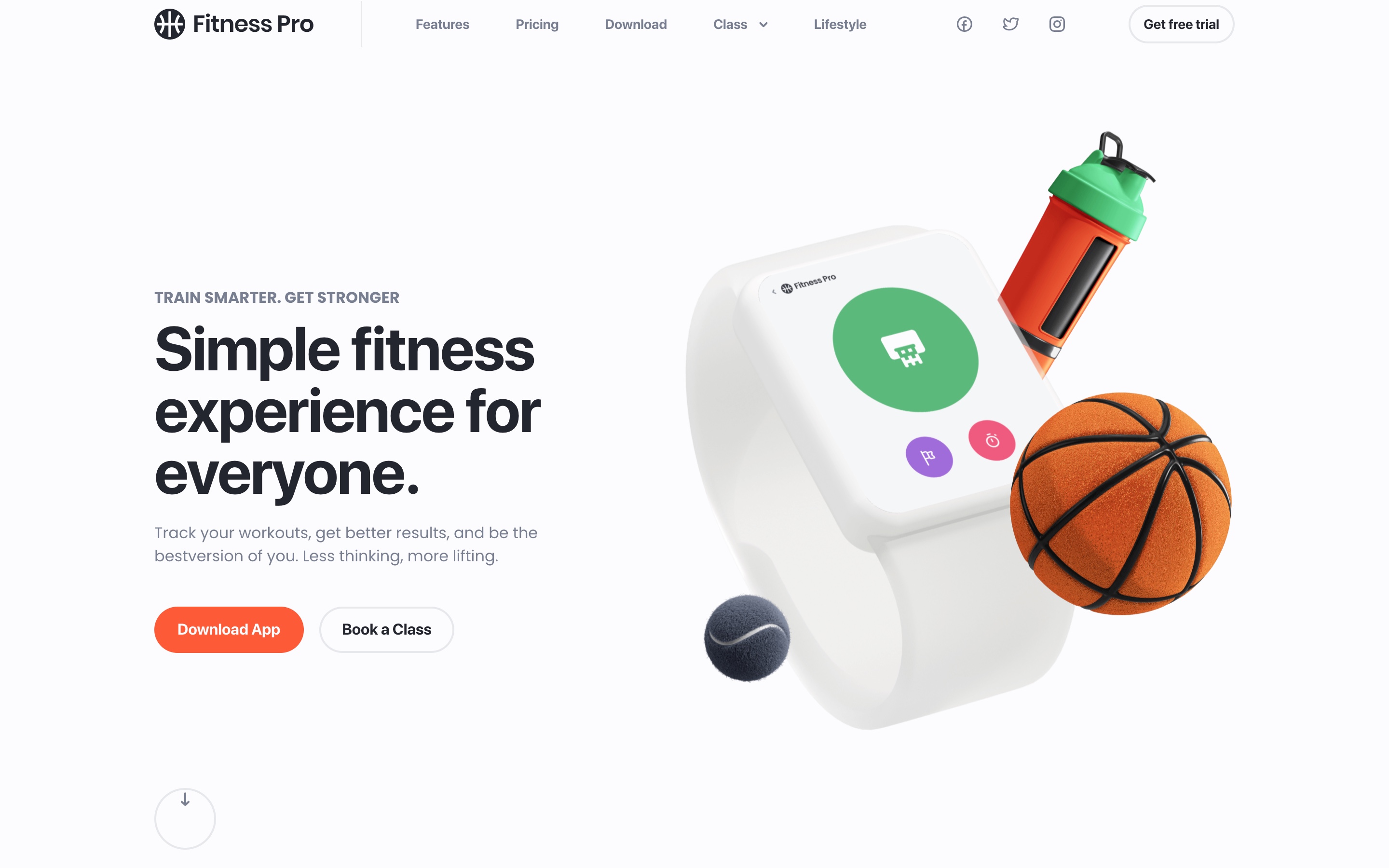

Here's What We Can Do

Produvia Process

Step 1. We discuss your project.

We schedule a call with you.

We schedule a discovery call to learn more about your goals, problems, or frustrations.

Step 2. We commit to working with you.

We send you a proposal, then a contract.

We send you a proposal with three pricing options. We follow-up with a contract and begin work.

Step 3. We launch your project.

We help you launch state-of-the-art technologies.

We research, develop, and deploy modern technologies, so you don't have to.

Produvia Benefits

Automate More

With our expertise and services, your business processes will be automated at scale, so you can focus on staying ahead of the game.

Innovate Faster

Produvia allows companies, businesses, and organizations to innovate 10x faster using artificial intelligence technologies. With Produvia you can go from idea to prototype in just days!

Generate Revenue

We are a creative agency with deep expertise in developing revenue-generating solutions for our clients. From large enterprise brands to innovative startups, we offer a unique combination of features you need to effectively monetize your products and services.

Reduce Costs

Running a company is difficult, but artificial intelligence technologies could help. According to expert estimates, AI technologies can reduce operational costs by up to 30%. The TÜV Rheinland experts have calculated that there are opportunities for companies to reduce costs.

Save Time

Let's face it, there's just not enough time in the day. AI can help. We develop AI technologies to free up your time, increase productivity, and help you lead a better life.

Ready to start?

Schedule a discovery call with Produvia and one of our team members will jump on a Zoom call with you.

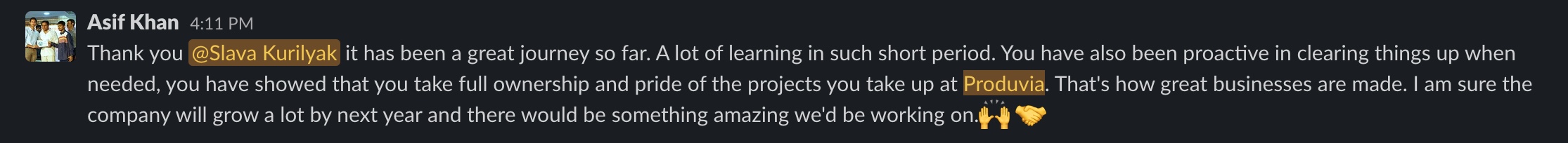

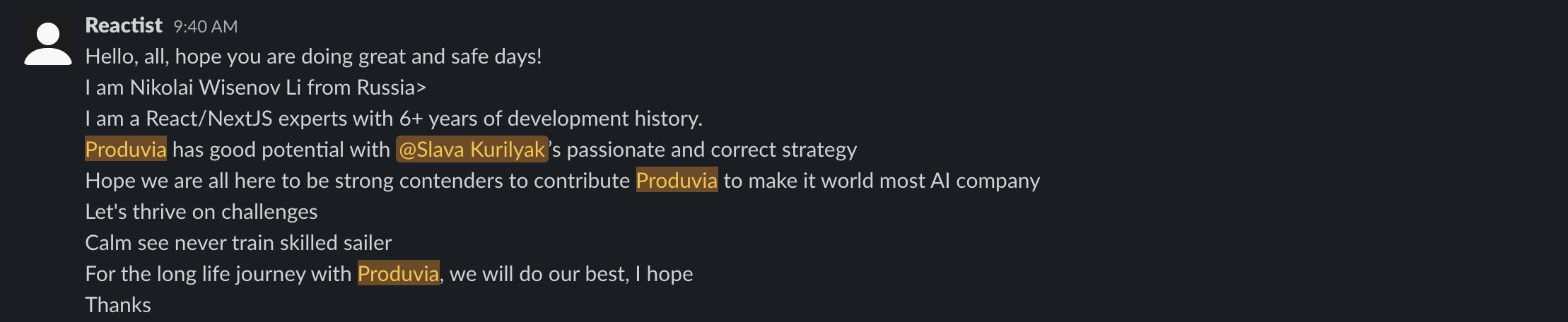

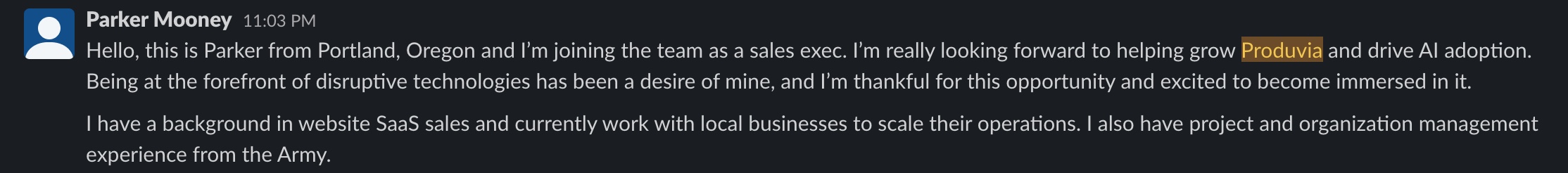

Team Testimonials

Produvia Blog

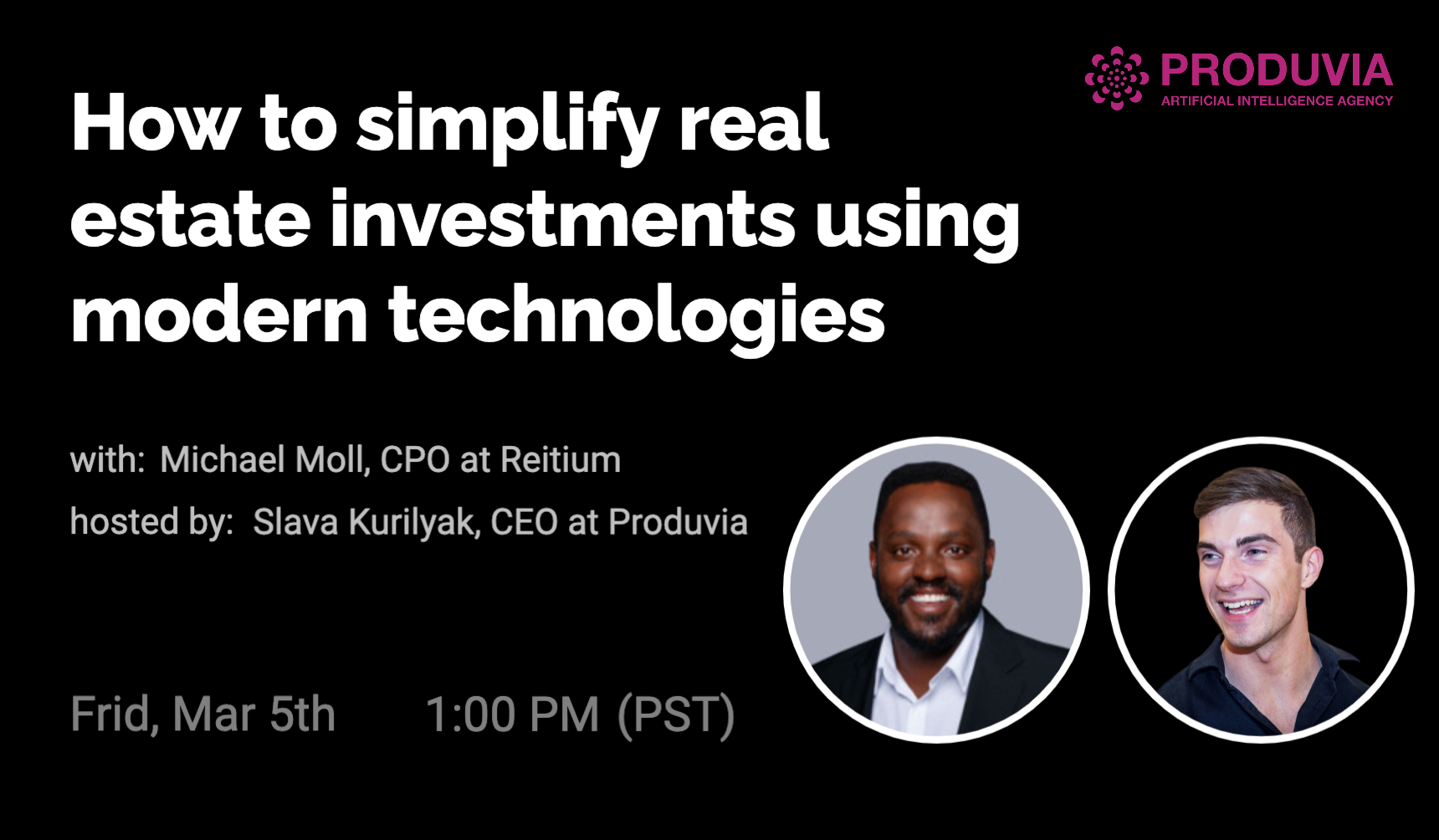

Produvia Live

Ready to scale?

Schedule a call with Produvia to learn how you and your team can scale faster.